The ever-evolving realm of technology, precision measurement tools play a crucial role in ensuring accuracy and reliability across various industries. One such cutting-edge instrument making waves is the co-axial blade probe. We'll embark on a journey to understand what a Co-Axial Blade Probe is and unravel the intricacies of its functionality.

What is a Co-Axial Blade Probe?

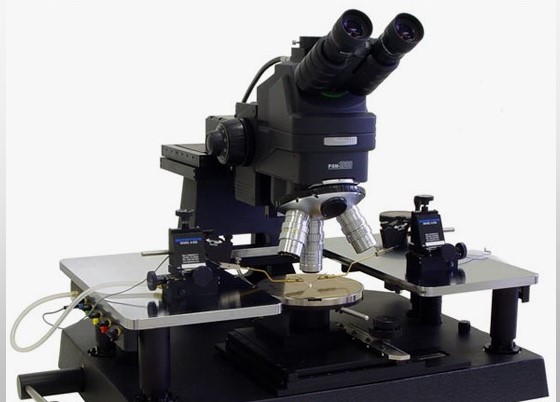

A co-axial blade probe, often referred to as a coaxial probe

or blade-style probe, is a specialized measuring device used in metrology and

quality control processes. It serves the purpose of obtaining accurate

dimensional measurements with high precision. Unlike traditional probes, the

co-axial blade probe features a unique design that sets it apart in terms of

performance and versatility.

Structural Components:

To comprehend the functioning of a co-axial blade probe,

it's crucial to understand its structural components. Typically, a co-axial

blade probe consists of the following key elements:

1. Blade Assembly:

At the heart of the co-axial blades and probe is the blade

assembly. This component is responsible for making contact with the surface

being measured. The blade is crafted with precision and is often made from

materials with excellent wear resistance to ensure longevity.

2. Co-Axial Configuration:

The term "co-axial" refers to the alignment of the

blade and the stylus within the probe. Unlike traditional probes, where the

stylus is offset from the blade, the co-axial design places both elements in

the same axis. This alignment enhances the probe's stability and allows for

more accurate measurements.

3. Internal Sensor Mechanism:

A co-axial blade probe incorporates an internal sensor

mechanism that detects the deflection of the blade upon contact with the

surface. This deflection is then translated into measurements, providing

precise data about the object's dimensions.

4. Mounting Interface:

To integrate seamlessly with coordinate measuring machines

(CMMs) or other measuring devices, co-axial blade probes are equipped with a

standardized mounting interface. This allows for easy attachment and

detachment, facilitating efficient use in various measurement setups.

How Does a Co-Axial Blade Probe Function?

Now that we have a grasp of its structure, let's delve into

the functioning of a co-axial blade probe.

·

Contact and Deflection

When a co-axial blade and probe come into contact with the

surface of the object being measured, the blade deflects. This deflection is a

result of the applied force and is a crucial aspect of the measurement process.

·

Sensor Response

As the blade deflects, the internal sensor mechanism within

the probe detects the amount of deflection. This sensor response is converted

into electrical signals, providing real-time feedback about the surface

conditions and dimensions.

·

Data Transmission

The electrical signals generated by the sensor are then

transmitted to the measuring instrument, typically a CMM or other compatible

device. These signals carry information about the deflection, allowing the

instrument to calculate precise measurements based on the probe's design and

specifications.

·

Data Analysis and Display

The final step involves the analysis of the transmitted data

and its presentation in a comprehensible format. This could include dimensional

data, surface profiles, or other relevant measurements. Modern co-axial blade

probes often interface with advanced software that enhances data analysis

capabilities and ensures accurate results.

Applications of Co-Axial Blade Probes:

The versatility and precision offered by co-axial blade

probes make them indispensable in various industries. Here are some notable

applications:

·

Aerospace Industry

In aerospace engineering, where precision is paramount,

co-axial blade probes find extensive use in measuring critical components such

as turbine blades and engine parts. The ability to capture intricate details

makes them a preferred choice in this demanding sector.

·

Automotive Manufacturing

The automotive industry relies on co-axial blade probes for

quality control in the production of components like gears, pistons, and other

intricate parts. The probes' high precision ensures that every manufactured

part meets stringent quality standards.

·

Medical Device Production

In the production of medical devices, where tolerances are

often in micrometers, co-axial blade probes contribute to the quality assurance

process. They are employed in measuring components for devices like pacemakers

and prosthetics.

·

General Metrology

Co-axial blade probes are widely used in general metrology

applications, providing accurate measurements for a range of objects and

materials. Their adaptability makes them a versatile tool in research and

development environments.

Advantages of Co-Axial Blade Probes:

Understanding the advantages of co-axial blade probes

further underscores their significance in precision measurement. Some key

advantages include:

·

High Precision

The co-axial design ensures that the probe's stylus and

blade remain precisely aligned, resulting in highly accurate measurements. This

level of precision is crucial in industries where small deviations can have

significant consequences.

·

Versatility

Co-axial blade probes are adaptable to various measurement

scenarios, making them suitable for a wide range of applications. Their

versatility enhances their value across different industries and measurement

environments.

·

Durability

Crafted from materials with excellent wear resistance, the

blades of co-axial probes exhibit durability over prolonged use. This

durability contributes to the longevity of the probe and ensures consistent

performance.

·

Ease of Integration

The standardized mounting interfaces of co-axial blade

probes facilitate seamless integration with different measuring instruments,

reducing setup time and enhancing overall efficiency.

Future Developments and Innovations:

As technology continues to advance, we can anticipate

further developments and innovations in the field of co-axial blade probes.

Researchers and engineers are likely to explore new materials, enhanced sensor

technologies, and improved data analysis techniques to push the boundaries of

precision measurement.

Conclusion:

The intricate world of metrology, Co-Axial Blade

Probes stand out as remarkable instruments, combining precision,

versatility, and durability. Their unique design and functionality make them

indispensable in industries where accurate measurements are paramount. As

technology continues to evolve, co-axial blade probes are set to play an even

more significant role in shaping the future of precision measurement.