The world of semiconductor manufacturing is a finely tuned orchestra of precision, innovation, and complexity. At the heart of this symphony lies the intricate process of semiconductor testing, a pivotal step in ensuring the functionality and reliability of these tiny electronic marvels. Among the unsung heroes of this process are probe card supplies – the unsung champions that enable the testing of semiconductors with unparalleled precision and efficiency. In this deep dive, we'll unveil the significance of Probe Card Supplies, unravel their components, and explore the pivotal role they play in the semiconductor industry.

The Semiconductor Ecosystem:

Before we plunge

into the realm of Probe Cards Maintenance Supplier, let's grasp the bigger

picture. Semiconductors are the fundamental building blocks of modern

electronic devices, from smartphones to supercomputers. These miniature wonders

consist of various electronic components, intricately etched onto a tiny piece

of silicon, and they are produced in semiconductor manufacturing facilities,

often referred to as fabs.

Semiconductor testing is a critical phase in the production of these chips. It's the equivalent of quality control in other industries, ensuring that each chip meets the stringent standards for performance and reliability. The process involves a series of tests to identify and eliminate defective chips, guaranteeing that only the finest components make it into our electronic gadgets

The Probe Card Gateway to the Semiconductor World:

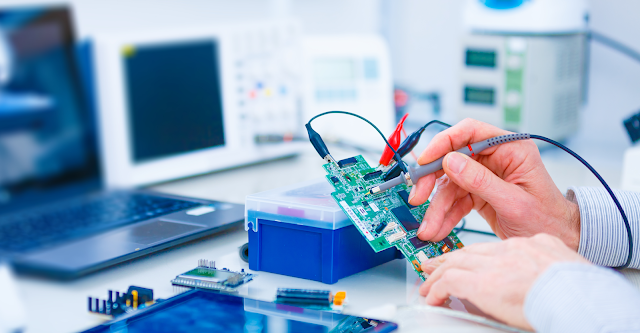

At the heart of semiconductor testing lies the probe card, a device that acts as a bridge between the semiconductor wafer and the testing equipment. Think of it as the conductor's baton, directing the testing instruments to perform their symphony of tests on the chip.

- Anatomy of a Probe Card

Let's dissect a probe card to understand its components and functions better:

- Needle-Like Probes

The probe card's most distinctive feature is its needle-like probes. These minute, precisely manufactured needles make physical contact with the semiconductor's contact points, allowing for the transmission of electrical signals for testing. Accuracy in manufacturing these probes is paramount, as even the tiniest imperfection can lead to erroneous test results.

- Ceramic Substrate

Beneath the probes lies the ceramic substrate, which acts as a foundation for the probes and provides electrical pathways for signal transmission. This substrate must have exceptional thermal and electrical properties to ensure reliable testing, as temperature fluctuations or electrical interference can skew results.

- Connectors and Wiring

The probes are connected to the testing equipment through a complex network of connectors and wiring. These connections must maintain the utmost integrity to prevent signal loss or distortion during testing.

- The Role of Probe Card Supplies

Now that we've

explored the core components of a probe card, let's delve into the essential

supporting actors – Probe Cards Maintenance Supplier. These supplies encompass

a range of materials and components crucial for the probe card's operation.

Unveiling The World of Probe Card Supplies:

- Probe Needles

The needle probes are the heart and soul of the probe card, and their quality directly impacts testing accuracy. Each needle must be meticulously crafted to exact specifications, ensuring consistent and reliable contact with the semiconductor wafer. The materials used for these needles are often advanced alloys, chosen for their durability, conductivity, and resistance to wear.

- Ceramic Substrates

Ceramic substrates are the canvas upon which the intricate circuitry of probe cards is painted. The choice of ceramic material is critical, as it must withstand the harsh conditions of semiconductor testing, including extreme temperatures and electrical stress. Advanced ceramics, such as alumina and silicon nitride, are favored for their exceptional electrical insulating properties and thermal stability.

- Connectors and Wiring

The connectors and wiring in a probe card supply kit are the unsung heroes that ensure seamless communication between the probe card and the testing equipment. High-quality connectors and wiring are essential to minimize signal loss and interference. Manufacturers often employ specialized materials, like gold-plated connectors, to enhance conductivity and reduce corrosion.

- Cleaning and Maintenance Tools

Probe cards and

supplies also encompass an array of cleaning and maintenance tools. Keeping the

needle probes free from contamination is critical for accurate testing.

Specialized brushes, cleaning solutions, and inspection tools are part of the

arsenal to maintain probe card hygiene.

The Crucial Role of Probe Card Supplies in Semiconductor Testing:

Now that we've introduced the components of Probe Cards Maintenance Supplier let's explore their indispensable role in the semiconductor testing process.

- Ensuring Accuracy and Reliability

The cornerstone of semiconductor testing is accuracy and reliability. A minor deviation in test results can lead to significant consequences, from faulty consumer electronics to critical failures in aerospace applications. Probe cards and supplies, particularly high-quality needle probes and ceramic substrates play a pivotal role in ensuring that every test is conducted with precision. They provide the stability and consistency necessary to produce reliable results.

- Minimizing Downtime

In the semiconductor industry, time is money. Any downtime in the manufacturing process can result in substantial financial losses. Probe cards and supplies that include robust connectors and wiring help minimize downtime by reducing the risk of connectivity issues. Moreover, the availability of cleaning and maintenance tools allows semiconductor manufacturers to quickly address any probe card-related issues and resume testing, keeping production lines humming.

- Extending the Life of Probe Cards

Probe cards are not cheap investments. They are sophisticated pieces of equipment that require protection and maintenance. High-quality Probe card maintenance Suppliers, including cleaning tools and maintenance kits, extend the life of probe cards by preventing premature wear and damage. This longevity translates to cost savings for semiconductor manufacturers.

- Enabling Advanced Testing Techniques

The semiconductor

industry is in a constant state of evolution, with chips becoming smaller,

faster, and more complex. To keep up with these advancements, Probe Cards

Maintenance Supplier must also evolve. Innovative materials and designs in

supplies enable advanced testing techniques, such as multi-site testing and

high-frequency testing. These capabilities are essential for evaluating

cutting-edge semiconductor components.

The Competitive Edge Choosing the Right Probe Card Supplies:

In the fast-paced world of semiconductor manufacturing, choosing the right probe card supplies can be a game-changer. The quality of supplies directly impacts the quality and efficiency of testing processes, which, in turn, affects a manufacturer's competitiveness and bottom line.

- Quality over Cost

While cost considerations are always important in any industry, sacrificing quality for a cheaper option when it comes to probe card supplies can be detrimental. High-quality supplies may come at a higher upfront cost, but they pay dividends in terms of reliability and longevity. Investing in a top-tier Probe Cards Maintenance Supplier is an investment in the future of semiconductor testing.

- Customization

Every semiconductor manufacturer has unique requirements, depending on the types of chips they produce and the testing techniques they employ. Probe cards and supplies should be customizable to meet these specific needs. Suppliers that offer tailored solutions, from probe needle materials to ceramic substrate specifications, provide a competitive edge by ensuring that testing processes are optimized for efficiency and accuracy.

- Supplier Reputation

A supplier's reputation in the semiconductor industry is a valuable indicator of the quality of their probe card supplies. Trusted suppliers with a history of providing reliable products and exceptional customer support are worth their weight in gold. Semiconductor manufacturers should seek out suppliers with a track record of delivering on their promises.

- Innovation and R&D Support

Innovation is the

lifeblood of the semiconductor industry. Probe Cards Maintenance Supplier

should not be stagnant; they should evolve alongside semiconductor technology.

Suppliers who invest in research and development to create cutting-edge supplies

are invaluable partners for manufacturers striving to stay ahead of the curve.

The Future of Probe Card Supplies:

As the semiconductor industry continues to push the boundaries of innovation, the future of probe card and supplies looks promising. Here are some key trends and developments to watch out for:

- Materials Advancements

Materials science will continue to play a pivotal role in the evolution of probe cards and supplies. Expect to see novel materials with enhanced electrical and thermal properties that enable even more precise and efficient testing.

- Miniaturization and High-Density Testing

The demand for smaller and more powerful electronic devices will drive the need for probe card supplies capable of testing high-density semiconductor wafers with microscopic precision. Advanced designs and materials will be essential to meet these demands.

- AI and Automation Integration

Artificial intelligence (AI) and automation are transforming semiconductor manufacturing. Probe card supplies will likely incorporate AI-driven features for real-time monitoring and adjustment during testing, further improving efficiency and reliability.

- Environmental Sustainability

As environmental

concerns gain prominence, expect to see probe card supplies designed with

sustainability in mind. This includes materials that are easier to recycle and

manufacturing processes with reduced environmental impact.

Conclusion:

In the intricate

world of semiconductor manufacturing, Probe card Maintenance Suppliers are the unsung heroes

that ensure the quality and reliability of the electronic devices we rely on

every day. From needle probes to ceramic substrates, these supplies are the

backbone of semiconductor testing, enabling manufacturers to produce chips with

unparalleled precision and efficiency.